Cutubka Koowaad

Hordhac Product

Jabiya iyada oo loo marayo fikradda naqshadaynta dhaqameed iyo farsamada wax-soo-saarka, sidoo kale waxay isku daraysaa suuqa sifooyin gooyo-gooyo ah, waxaan si madax-bannaan u horumarinay mashiinka tolida wareegyada.

Codsiyada:

Bustayaal, roogaag, dhogorta shacaab, tuulmo sare, dhar geed, cashmere, dhogorta PV, cashmere caws iyo dhammaan noocyada dharka.

Xogta farsamada:

Qaabka: YF3012;YF3016;YF3020;YF3214;YF3218;YF3222;YF3418;YF3420;YF3422;YF3620;YF3622;YF3822;YF3824;YF3826;YF3828;YF4022;YF4026;YF4030;YF4428;YF4432

Dhexroor dhululubo: 30-38inch

Qiyaasta Cirbadda: 14G-32G

Quudiye: 12F-32F

RPM: 1-23r/min

Awoodda: 4kw, 5.5kw

Dhererka tuulan: 4-25, 25-50mm

Cutubka Labaad

Dejinta iyo Rakibaadda

Soo dejinta ugu weyn

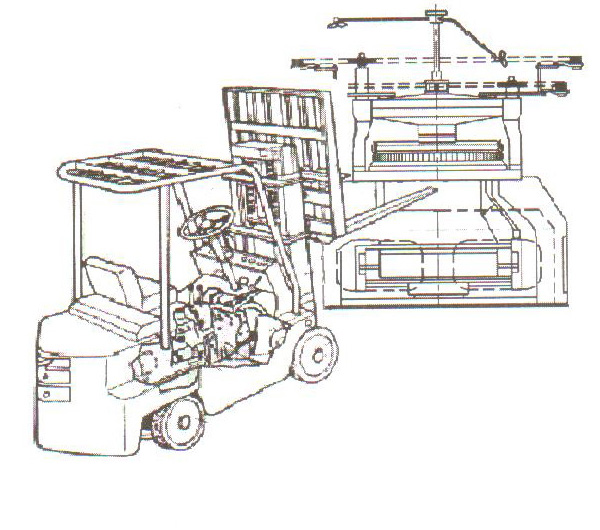

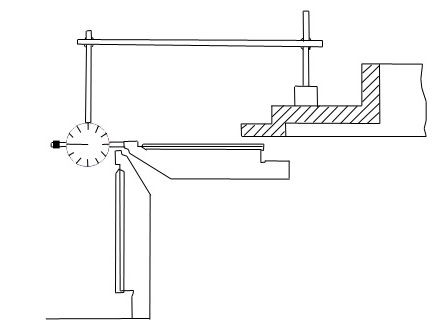

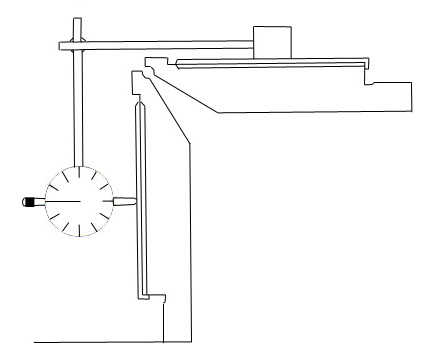

Isticmaal wax ka badan 5 ton oo fargeeto ah si aad u dejiso jir, habka sida ku cad shaxanka 1-1, pl akhritilmaamaha hoos ku qoran:

1.Ka hor inta aan la dejin, u dhaqaaq nidaamka gudbinta gacanta si aad u sameyso dib-u-celinta maryaha inay la mid tahay cagta ugu weyn (sida caadiga ah, mashiinnada ayaa ku jiray xaaladdan ka hor intaan la keenin).

2. Ku dheji gacanta fargeetada labada cagood dhexdooda si tartiib ah, oo si toosan uga soo qaad xagga hoose (fiiri: ku dheji alwaax ka mid ah cududda iyo mashiinka dhexdooda, si aad isaga ilaaliso dhaawaca sababtoo ah silbashada mashiinka inta lagu jiro dejinta)

3. Inta lagu jiro dejinta, ku hay mashiinka qiyaastii 30-50cm dhulka ka sarreeya, ha u ogolaanin inuu ku socdo waddo adag, looma oggola inuu istaago ama u dhaqaaqo si lama filaan ah, oo si taxadar leh kor iyo hoos u iftiimi.

4.Haddii mashiinku uusan gaarsiin warshadda macaamiisha, fadlan hubi inaad dhigto meel qallalan oo nadiif ah, si looga fogaado in ay saameyn ku yeelato dame iyo daxalka, si looga fogaado isticmaalka caadiga ah ee mashiinka.

Goobta mashiinka iyo rakibida:

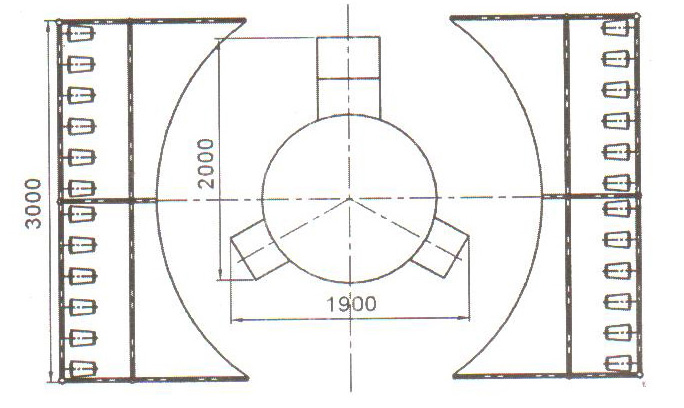

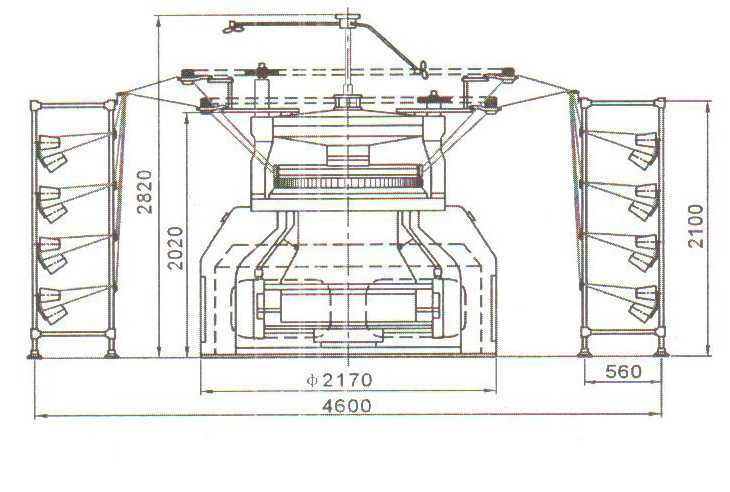

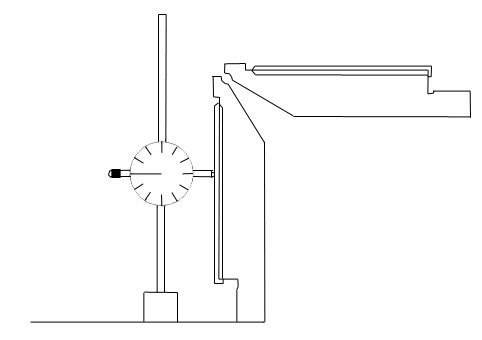

1.Kahor intaadan hagaajin booska, cabbir booska jir iyo kareem si aad u xaqiijiso booska rakibaadda, iyadoo loo eegayo cabbirka shaxanka 1-2

2.Ka dib markii la hagaajiyay booska, isticmaal gradienter si aad u hagaajiso dusha mashiinka si taxadar leh (waxay hagaajin kartaa cagaha cagaha ee ugu weyn iyo cagaha, si loo hubiyo in qaladka lateral aan ka badnayn 5mm)

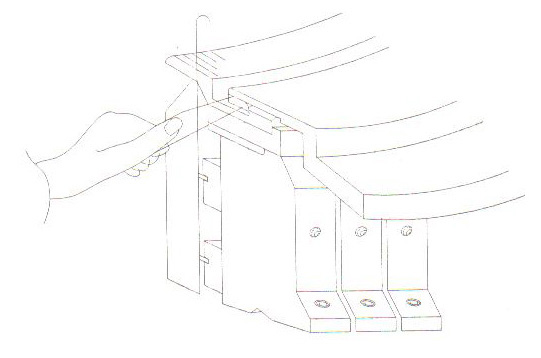

Goobta iyo isku dhafka jilibka

1. Xaqiiji booska jilbiska si waafaqsan shaxanka 1-2 cabbirka.

2.Ku xidh tiirka cylindrical oo wuu wareegayaa, oo deji qaabka jilbiska

3.Ku rakib afar xabbo oo aluminium ah oo dhumuc weyn leh oo ku yaal dhinaca dambe ee jilitaanka (si loo rakibo marinka tuubada dunta), iyo afarta kale ee khafiifka ah waa in lagu rakibaa ka hor inta aan la saarin (si loo rakibo qalabka wax lagu riixo)

4.The height of yarn quudinta strips aluminium waa in ay ka sarreeyaan aluminium cadaadis, sidaas darteed marka tolida, quudinta dundu waxay noqon doontaa siman, si fudud ma jebin doonaa.

5.Ku rakib qalabka madbacadaha ee xariijimaha aluminiumka hore, ku dheji marinka tuubada dunta creel ee xariijimaha aluminiumka dambe.Hayso masaafo isku mid ah si aad uga fogaato quudinta dunta.

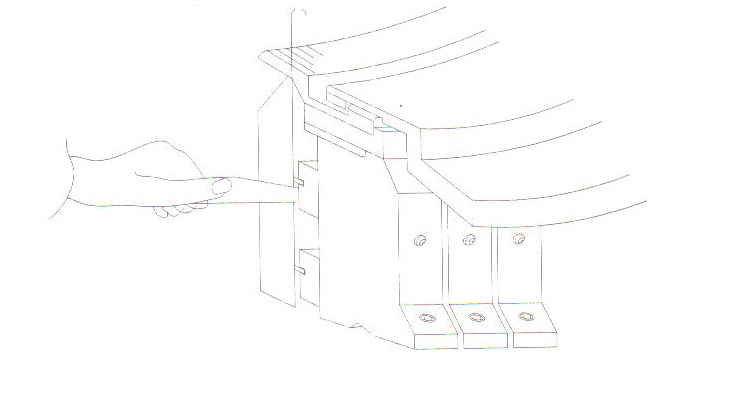

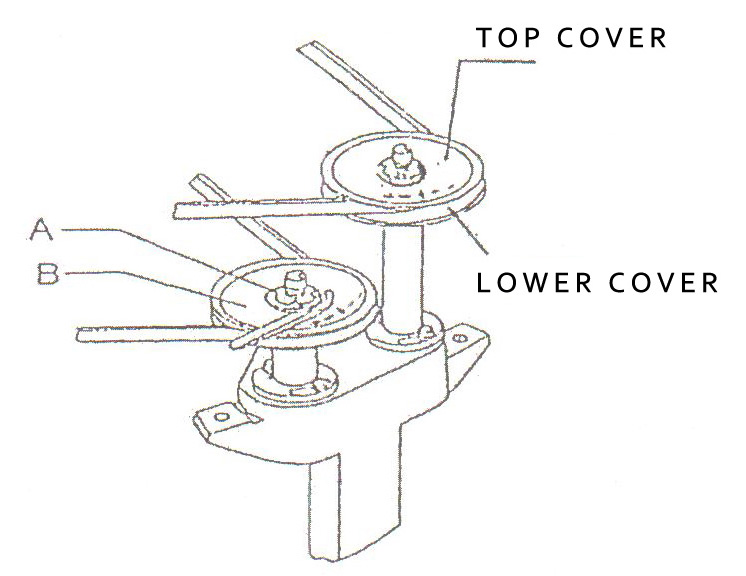

Isku darka dunta diritaanka

1.Rakib oo hagaaji mashiinnada quudinta dunta beddelka iyo tiirarka

2.Install ka kor wareeg ah, qalab kaydinta dunn kor iyo si toos ah qalabka joogsiga fiilooyinka korontada.

3.Install qaab wareeg ah hoos, qalabka kaydinta dunn hoose iyo si toos ah qalabka joogsiga fiilooyinka korontada.

4.Rakib suunka gudbinta kor iyo hoos.

5.Ku rakib kor iyo hoos boodhka ururiyaha, fiiro gaar ah u yeelo si aad u hagaajiso booska marawaxada.

6.Adjust saxan aluminium dunn ah

7.Connect awoodda qalabka joogsiga si toos ah.

Cutubka Saddexaad

Halbeegga Farsamada iyo hagaajinta aasaasiga ah

Dhammaan mashiinadayadu waxay ku socdaan duritaanka adag, hagaajinta iyo shaqada Komishanka ka hor dhalmada (dhammaan mashiinku waa inuu shaqeeyaa in ka badan 48 saacadood)

Heerarka farsamada

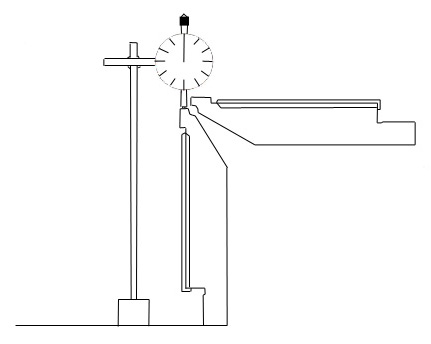

1. Self planeness ee garaaca irbadda kor

Heerka ≤0.05cm

2. Is-wareejinta garaaca cirbadda kor

Heerka ≤0.05cm

3. Is-wareejinta durbaanka cirbadda hoose

Heerka ≤0.05cm

4.Saf-u-dhigista durbaanka irbadda ee hoos

Heerka ≤0.05cm

5.Isla midka ah ee garaaca irbada un iyo durbaanka cirbadda hoos u dhaca

Heerka ≤0.05cm

6. Isku wareeg isku mid ah garaaca cirbadda kor iyo durbaanka cirbadda

Heerka ≤0.05cm

7.Space u dhexeeya kamaradaha kor iyo durbaanka irbadda

0.15mm-0.25mm

8.Space u dhexeeya kamaradaha hoose iyo durbaanka irbadda

0.15mm-0.25m

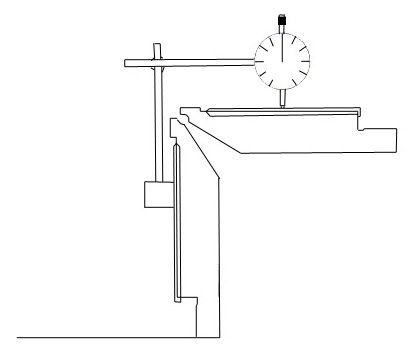

Hagaajinta aasaasiga ah

Caadi ahaan, mishiinkeena waxa lagu duraa irbad adag ka hor dhalmada, laakiin si laguugu ogolaado inaad isticmaasho mishiinka badbaado badan, pl hubi oo hagaaji isticmaalka ka hor.

1. Hubi matoorka

Ku xidh awoodda, oo hubi jihada wadista matoorka, haddii jihadu ka duwan tahay calaamadda mishiinka, beddel fiilooyinka mootada isla markiiba (isweydaarsiga laba ka mid ah saddexda weji ee matoorka).

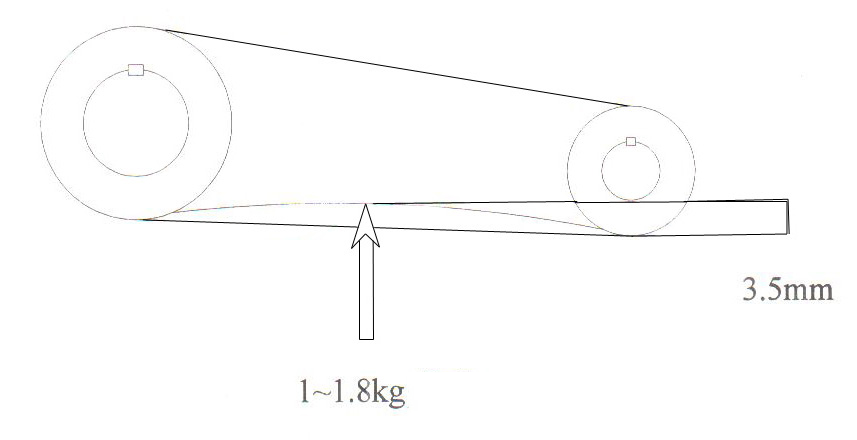

2.Check iyo hagaajinta suunka wadista matoorka

Shaqada ka hor, hubi xiisadda suunka wadista matoorka.Hel 1-1.8kg xoogga dhexe ee suunka, samee qallafsanaanta tooska ah ee suunka in ka yar 3.5mm, hagaaji ilaa inta aad ka buuxineyso shuruudaha.Hagaajin habka: fur fur furka matoorka, hagaaji xiisadda mootada hagaajinta koofiyadda xariirta, ilaa ay xiisaddu ka soo baxdo shuruudaha, oo adkee furka.

Fiiro gaar ah: saddexda maalmood ee ugu horreeya, dib u hubi hal mar, oo hubi saddexdii biloodba mar.

3.Blowing nidaamka hagaajinta

Taageeraha nidaamka afuufidu wuxuu u baahan yahay inuu si gaar ah u hagaajiyo, ilaa taageeruhu uu ku yaal booska ugu fiican.Markaa marka korontadu shido, marawaxadu waxay afuufi kartaa gees kasta oo ka mid ah quudinta dunta.

4.Hagaajinta nidaamka gudbinta dunta

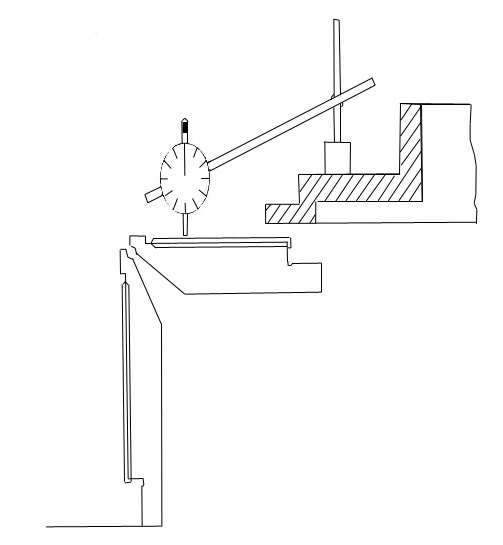

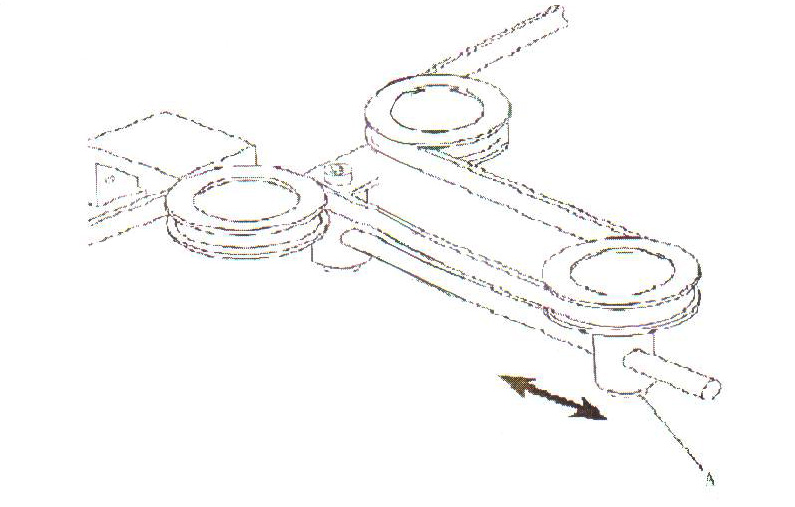

(1) Hagaajinta yar ee saxan aluminium quudinta dunta.

Beddel dhexroorka dunta quudinta saxan aluminium ah, saamiga gudbinta waa la beddeli doonaa, qadarka quudinta dunta waa la beddeli doonaa.Hababka ayaa ah kuwan soo socda:

①Marka hore, isticmaal furaha si aad u dabciso lowska wareega A ee sare ee dunta quudinta saxan aluminium ah.

② U rog daboolka jihada "+", 12 sliders ee gudaha saxanku waxay balaadhi doonaan dibadda, si loo kordhiyo dhexroorka taayirka, oo ay kordhiyaan tirada quudinta dunta.Taa beddelkeeda, u wareeg "-", tirada quudinta dunta ayaa yaraan doonta.Markaad wareegeyso, isbarbar dhig, haddii kale, sliders-yada ayaa laga yaabaa inay ka soo dhacaan booska.

Dhexroorka kala duwan ee saxan aluminium quudinta dunn noqon doonaa: 70-202mm

④Ka dib markaad saxanka hagaajiso, dib u celi lowska wareega.

(2) Isku hagaajinta xiisadda suunka gudbinta quudinta dunta

Haddii suunka uu aad u dabacsan yahay, qalabka kaydka dunta ayaa simbiriirixi doona oo fadhiisan doona, oo saamayn doona quudinta dunta.Markaa ka hor intaanad shaqada gelin, u hagaaji gudbinta quudinta dunta sida ugu fiican sida hoos ku qoran:

① fur furka A

② U soo jiid giraangiraha rogrogmada dibadda ah ee la socda slider, hubi in diiqada suunka ee kaydinta dunta ay isku mid yihiin.

③ quful furka A

1. hubinta saliidda dufanka

Hubi subagga qayb kasta oo ka mid ah nidaamka gudbinta iyo nidaamka rogrogmada maro, haddii ay jiraan wax aan caadi ahayn, waqti ku dar saliidda dufan

Cutubka Afraad

Dhibaatooyinka caadiga ah inta lagu jiro tolitaanka

Dalool

Waxa ugu weyn ee ay keento dunta qallafsan

Sababtoo ah dun tayo xun ama aad engegan

· Meel khaldan oo dunta quudinta afka

· Xiisadda duntu aad bay u weyn tahay ama xiisadda duuban ayaa aad u weyn

Cufnaanta gariiradda ayaa aad u sareysa

Goobabada tolashadu aad bay u dheer tahay, dharkuna aad buu u dhuuban yahay

Irbad maqan

· Meel khaldan oo dunta quudinta afka

· Xiisadda duntu aad bay u yar tahay

Goobabada tolida ayaa aad u dheer

· Godka afka quudinta oo aan sax ahayn

· Afka quudinta dunta dushiisa oo aad u sareysa

ifafaale Tuck

·Xiisada isku xidhan waa mid aad u yar

Cufnaanta marada ayaa aad u sareysa

· Carrabka irbadda ayaa dhaawacday

Dhaawaca carrabka

Booska afka quudinta oo aad u sarreeya, aad u hore ama gadaal, u fiirso haddii duntu soo gashay afka quudinta.

Isku dhaca irbadda

Saliid la'aan ama isticmaal aan habboonayn

· Tayada duntu aad bay u dalooli kartaa ama kareerku kuma habboona cabbirka

Xawaaruhu aad buu u sarreeyaa ama cufnaanta maradu waa mid aad u sareysa

Waxa sababay durbaanka irbadda ee jaban, garaaca irbadda ama kamarad

Asalka tolida ma fududa, nadiif kuma filna

Farqiga u dhexeeya garaacista tolida iyo durbaanka ayaa qaldan

Xariijimo

Isku hagaajin aan habboonayn oo xiisadda dunta korka ah

Tayada duntu way kala duwan tahay

Hagaajinta booska aan saxda ahayn ee giraangiraha dhogorta cadaadiska

Si aan sax ahayn loo hagaajiyo xiisadda dunta hoose

Baar

Middi ma af badan

· Boodhka mindida oo aad u badan, iyo jillaab mindidu aad bay ugu dheggan tahay

Saliid la'aan, qadarka saliiddu aad bay u yartahay

Cutubka Shanaad

Dayactirka

Xawaaraha sare iyo saxda ah ee saxda ah ee mashiinka dharka casriga ah wuxuu u baahan yahay codsi sare oo dayactir ah, sidaas darteed, shirkadeena waxay si dhab ah u soo koobtay qaar ka mid ah habka dayactirka ee shaqada maalinlaha ah, waxaan rajeyneynaa in macaamiishu ay u hoggaansami karaan talooyinka, si ay u sameeyaan mashiinka u shaqeeyo xaaladda ugu fiican.

Isticmaalka hore iyo dayactirka mishiinka

1.Marka mishiinku dhammeeyo rakibidda oo uu bilaabo inuu soo saaro, xawaaruhu ma noqon karo mid aad u dhakhso badan, inta lagu jiro usbuuca ugu horreeya ee saacadaha 20 maalintii), xawliga ku hay 10r / min.hal usbuuc ka dib, si tartiib tartiib ah u hagaaji xawaaraha si caadi ah

2.Bisha ugu horeysa waxa iska leh muddada run-in, hal bil ka dib, beddel saliidda mishiinka ee mashiinka, oo beddela saddexdii biloodba mar.

3.Keep saliidda mashiinka 1 / 2-2 / 3 ee heerka saliidda, bixi waqti ku habboon marka saliiddu yaraato, si looga fogaado waxyeellada saxanka xirashada oo sababa qufulka mashiinka

Dayactirka maalinlaha ah

1. Nadiifi siigada ku dheggan dunta dunta iyo mashiinada oogihiisa, si aad u nadiifiso qaybta tolitaanka iyo qalabka wax lagu duubo

2. Hubi aaladda joogsiga tooska ah iyo aaladda badbaadada xilli kasta, haddii ay jiraan wax aan caadi ahayn, hagaajin ama beddel isla markiiba.

3. Hubi aaladda quudinta dunta xilli kasta, haddii ay jiraan wax aan caadi ahayn, isla markiiba hagaaji

4. Hubi muraayadda saliidda mashiinka iyo tuubada heerka saliidda booyadaha

Dayactirka toddobaadlaha ah

1. nadiifi quudinta dunta Xawaaraha aluminium, oo nadiifi kaydka boodhka ee saxanka

2. Hubi in xiisadda suunka ee gudbintu ay tahay mid caadi ah, iyo in gudbintu ay joogto tahay

3. Hubi wareegga mashiinka duubista dharka

Dayactirka bishii

1. Ka saar dhammaan sanduuqa, si aad boodhka u nadiifiso

2. Nadiifi boodhka ka saar marawaxad oo hubi in jihada dabayshu ay sax tahay.

3.Ka nadiifi boodhka dhammaan qalabka korontada ku shaqeeya

4.Dib u eegis waxqabadka dhammaan qalabka korantada oo ay ku jiraan nidaamka joojinta otomaatiga ah, nidaamka digniinta badbaadada, nidaamka hubinta)

Dayactirka sannadlaha ah

1. Nadiifi dhammaan cirbadda garaaca iyo irbadda, hubi dhammaan irbadaha, haddii ay jiraan wax dhaawac ah, isla markiiba beddel

2.Nadiifi mashiinka buufinta saliidda oo hubi in saliiddu aanay xannibnayn

3.Nadiifi oo hubi qalabka kaydinta dunta

4.Nadiifi boodhka iyo saliida matoorka iyo habka gudbinta

5. Hubi in ururinta saliidda qashinka ay tahay mid aan xannibnayn

Dayactirka sanadlaha ah

1. Qaybaha tolida waa wadnaha mashiinka tolida, waa si toos ah loo hubiyo tayada dharka, o, runtii waa muhiim in la ilaaliyo qaybaha tolida

2.Nadiifi jeexdin irbadda, si aad isaga ilaaliso boodhka dharka tolida.Habka: ku beddel dunta dunta tayada hoose ama dunta qashinka ah, ku fur mishiinka xawaare sare, oo saliid tiro badan ku dur silinka, Ka shaqee marka shidaal lagu shubayo, ilaa saliidda qashinka gebi ahaanba ka baxayso godka.

3. Hubi in ay jirto wax cirbad ah oo dhaawacmay, haddii ay haa tahay, isla markiiba beddel;haddii tayada dharku aad u xun tahay, waa in aad tixgelisaa in dhammaan cusbooneysiinta.

4. Hubi in jeexdin dhululubo uu la mid yahay masaafo la mid ah (ama hubi in dusha sare ee maradu ay leedahay xariijimo), haddii gidaarka jeexdin irbadda uu yahay mid adag.

5. Hubi xaalada xidhashada kamaradaha, oo hubi in meesha rakibaadda ay sax tahay iyo in boolalku ay dhagan yihiin

6. Hubi oo sax meel kasta oo afka quudisa dunta, haddii ay jiraan wax dhaawac ah, isla markiiba beddel.

7.Check booska rakibaadda ee kamarad kasta oo cidhiidhi ah, si loo hubiyo in dhererka dhar kasta uu isku mid yahay

Habka saliidda, saliidda iyo saliidda

1.habka saliida iyo saliida

(1) Ka eeg dial-ka iyo mashiinka duubista dharka maalin kasta, haddii saliiddu ka yar tahay 2/3, ku dar saliidda.Isticmaal N10#-N32# saliid mashiinka.Marka dayactirka nuska sano ah, haddii ay jiraan wax boodh saliid ah, isla markiiba beddel.

(2) Hubi qalabka saldhigga ee dhululubada bil kasta, ku dar dufan, isticmaal dufanka Lithium No.3

(3) Markaad ilaaliso nuskii sano kasta, hubi orso kasta oo gudbinta, ku dar dufan, isticmaal dufanka saliidda lithium No.3.

(4) Dhammaan sifaynta qaybaha tolida waa inay isticmaalaan saliid tolida (oo ay ku jirto saliidda mishiinka la isku duro), sida saliidda mashiinka tolida ee wareegyada xawaaraha sare ee England.

2.Sifeyn

Si fiican u ogow nooca saliidda iyo wakhtiga saliidda ee qayb kasta, si aad u hubiso in dhammaan mishiinka lagu saliidayn karo wakhtiga loo qoondeeyay saliid go'an iyo qiyaasta qiyaasta.

Wakhtiga dhimista iyo tixgelinta la xidhay

Dayactirka mishiinka iyo daryeelkiisa waa in loo maamulaa iyadoo loo eegayo habraaca dayactirka sanadka badhkii, marka hore waxaad ku dartaa saliida saliidda ee qaybaha tolida, ka dibna ku biir saliida lidka-dixalka ee irbadda todashada, ugu dambayntiina ku dabool mishiinka daamur kaas oo qooyay saliid irbad oo lagu xidhay qalalan oo nadiif ah. meel.

Kaydinta agabka mishiinada iyo agabka dheeriga ah

Qayb la isticmaalo oo degdeg ah, kaydka caadiga ahi waa dammaanad muhiim u ah sii wadida wax soo saarka.Deegaanka wax lagu kaydiyo waa inuu ahaadaa mid qabow, qalalan iyo kala duwanaansho yar oo heerkulka, hubinta joogtada ah sidoo kale waa lagama maarmaan.

Habka kaydinta waa sida soo socota:

1. Kaydinta irbadda dhululubada iyo garaaca irbadda

Marka hore nadiifi cirbadda dhululubada, ka dibna ku rid sanduuqa alwaax ee lagu riday saliidda mashiinka iyo duubka marada saliidda, si looga fogaado kuuskuus iyo qallafsanaan.Markaad isticmaalayso hawada cufan si aad uga saarto saliidda mashiinka gudaha cirbadda dhululubada, ka dibna ku dar saliid irbadda.

2.Kaydinta kamaradaha

Kala sooc kamaradaha oo ku rid kaydinta, kaas oo lahaa kaydinta sanduuqa oo ku dar saliid antirust si looga fogaado miridhku.

3. Kaydinta irbadda tolitaanka

(1) Irbada cusub ee tolida waa in lagu ridaa sanduuqa baakadaha asalka ah, hana ka saarin shaabadda.

(2) Irbadda tolitaanka duugga ah waa inay nadiif ahaataa, hubisaa, soo saartaa kuwa dhaawacan, kala saarta oo ku rid kaydinta saliidda cirbadda si looga fogaado miridhku.

Dayactirka qaybaha korontada

1.Muhiimada dayactirka

Wareegga mashiinka tolida wuxuu ka kooban yahay qayb elektaroonik ah oo sax ah ——rogidiyaha.Codsiyada wax ku oolka ah, sababtoo ah heerkulka ku hareeraysan, qoyaanka, gariirka, boodhka, gaaska daxalka ah iyo arrimaha kale ee deegaanka, isku halaynta iyo nolosha adeegga beddelka ayaa si xun u saameyn doonta.Haddii si sax ah loo ilaaliyo, ma aha oo kaliya in la hubiyo in la isku halleyn karo laakiin sidoo kale in la kordhiyo nolosha adeegga, waxayna yareyn doontaa khasaaraha wax soo saarka ee ay keento fashilka marmar.Sidaa darteed, dayactirka joogtada ah ee wareegyada inverter iyo wareegyada durugsan waa lagama maarmaan.

2. Hubi wareegyada rogrogayaasha iyo wareegyada durugsan

Rogayaasha shaqada ordaya iyo wareegyada kontoroolka, badanaa waa inay sameeyaan jeegaga soo socda:

(1) Heerkulka deegaanka: Caadi ahaan guud ahaan - 10 ℃ ~ + 40 ℃ kala duwan, at 25 ℃ ama sidoo kale.

(2) danab galiyaha inverter: qiyaasta caadiga ah waa 380V ± 10%.

(3) Nadiifinta joogtada ah ee duqsiga hoos, boodhka sanduuqa kantaroolka si aad u ilaaliso sanduuqa korantada gudaha nadiifinta, waxay soo jeedisay in la nadiifiyo hal mar maalintii ka dib isbeddelka shaqada.

(4) Saliiddu waxay dedejin doontaa fiilooyinka gabowga, haddii sanduuqa korantada ee ku jira si lama filaan ah saliidda, fadlan nadiifi wakhtiga.

(5) Si joogto ah u hubi marawaxada qiiqa ee sanduuqa korantada, haddii ay waxyeelo soo gaadho fadlan beddel wakhtiga, si aad u hubiso in heerkulka gudaha ee sanduuqa korantada aanu aad u sareyn.

3. Kormeer joogto ah

Isticmaalka wakhtiga dib-u-habaynta qalabka sannadlaha ah, oo waxaad kormeerka saartaa xoogaa inverter-ka gudaha ah.

(1) Marka la samaynayo dayactirka joogtada ah, waa in la gooyaa korontada ka hor inta aan la hawlgalin ilaa tusaha korantada baska DC ee gadwadeenka ka maqan yahay, badiyaa in ka badan hal daqiiqo (awood weyn ee inverter, wakhtiga sugitaanka dheer), ka dibna fuliyaan. qalliinka.

(2) Burburi daboolka ka baxsan rookaha, adoo faaruqinaya guddiga wareegga wareegga iyo qaybaha IGBT gudaha, gelinta iyo wax soo saarka iyo qaybaha kale.Isticmaal maro suuf ah oo leh qaar ka mid ah walxaha nadiifinta gaarka ah si aad u tirtirto meelaha wasakhaysan ee sabuuradda wareegga.

(3) Hubi dahaarka siliga sunta rasaasta gudaha ee inverter haddii uu leeyahay daxal ama raad jabay, marka la helo waa in si degdeg ah loo daweeyaa ama loo beddelaa.

(4) Gariirka, heerkulka isbeddelka iyo saameynaha kale awgeed, qaar ka mid ah unugyada isku dhejinta ee rookaha sida furka ayaa had iyo jeer noqda kuwo dabacsan, waa in ay adkeeyaan dhammaan furaha mar kale.

(5) Hubi oo hel in reactors-ka wax-soo-gelinta iyo kuwa wax-soo-saarka, Transformers, iwm. ay yihiin kulayl xad-dhaaf ah, daadsan, dahaarka cilladaysan, midab beddela oo gubtay ama ay ur leeyihiin.

(6) Hubi in dhexdhexaadiyaha DC ee shaandhaynta korantada korantada ee awoodda iyo waxqabadka lacag-bixinta ay wanaagsan tahay, haddii muuqaalku leeyahay dildilaacyo, daadinta, bararka, iwm., nolosha adeegga capacitor filter waa 5 sano, muddada baaritaanka ugu dheer waa hal sano. , oo shan sano ka dib fadlan beddel.

(7) Hubi in hawlgalka marawaxad qaboojintu uu xaalad fiican ku jiro, haddii la helo buuq aan caadi ahayn, gariirka aan caadiga ahayn waa in isla markiiba la beddelaa.Haddii kale inverter-ku wuu kululaan doonaa, wuxuuna saamayn doonaa nolosha qalliinka beddelka.Wareegga beddelka marawaxadu guud ahaan waa 2-3 sano.

(8) Hubi caabbinta dahaarka ee inverter haddii uu ku jiro heerka caadiga ah (Dhammaan terminaalka iyo terminaalka dhulka), Ogow inaadan isticmaali karin megameter-ka si aad u cabbirto guddiga wareegga, haddii kale waxay dhaawici doontaa qaybaha elektiroonigga ah ee guddiga wareegga.

(9) Ka saar fiilada R, S, T inverter terminalka dhamaadka korantada, ka saar fiilada U, V, W terminal dhamaadka mootada, cabir dahaarka u dhexeeya kaari weji kasta oo fiilada iyo ilaalinta grounding megameter haddii buuxi shuruudaha, caadi ahaan waa in uu ka weyn yahay 1MΩ.

(10) Ka hor inta aan la gelin inverter shaqada taas oo dayactirka la dhammeeyey, inverter waa in load matoor iyo tijaabiyo dhawr daqiiqo, xaqiijiyo jihada wareeg ee motor.

Waqtiga boostada: Abriil-20-2022